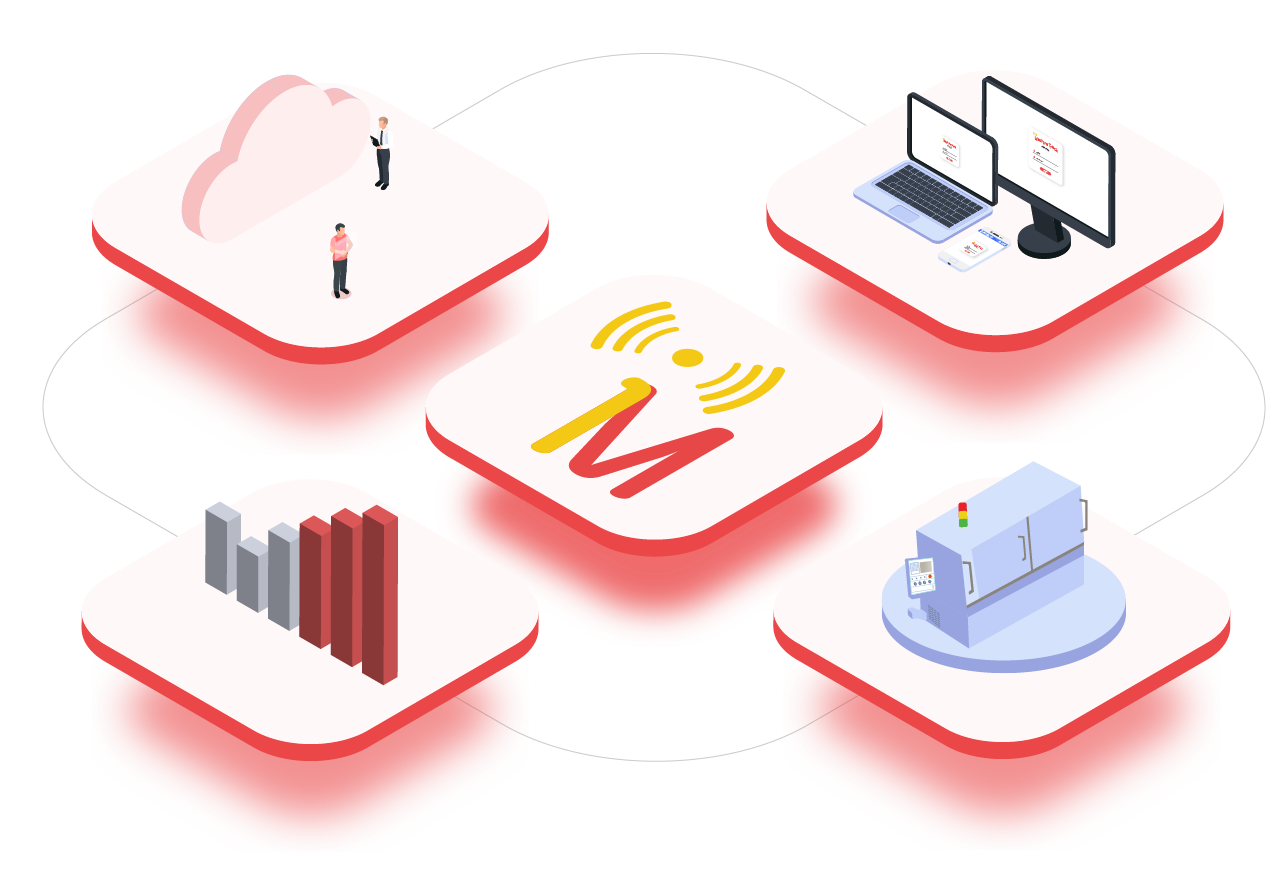

An edge based plug and play digitization tool for production floor monitoring.

About iMachineTrack

iMachineTrack provides necessary information at the right time to the right people for making the right decisions. iMachineTrack will help you in analyzing the real time data and improve the overall equipment efficiency (OEE) and Total Effective Equipment Performance (TEEP).

iMachineTrack helps in keeping track of OEE, Machine Utilization and downtime in real time for improving the production efficiency.

With Analytics, Team can make quicker decisions in the improvement of the process for increasing productivity and efficiency.

Pre Plan your maintenance schedules and keep the machines running longer and healthier.

HOW IT WORKS

iMachineTrack collects the real time data from multi brand CNC machines irrespective of controllers by using appropriate protocols like OPC UA/DA.

BEST SERVICES

Data collection can be done in various protocols like MT connect, OPC UA/DA, modbus, profibus etc with the help of various controllers like mazak, fanuc, mitsubishi etc.

We can connect and collect the data in less than 20 minutes and deploy the product in less time.

N number of machines can be connected and collect the real time data seamlessly without any data loss.

Product is of one time cost to the organization. There are maintenance charges involved to run the product for monitoring.

There are no hidden costs involved. Absolutely we offer the best price in the market. Complete transparency is maintained in costing.

Any future updates/releases in the software can be done in real time without much ambiguity.

Testimonials

Testimonials

Testimonials

RECENT PROJECTS

RECENT ARTICLE

In manufacturing plants, business applications are playing a major […]

Book a tailored demonstration of iMachineTrack that aligns with your specific manufacturing needs.